组合式不锈钢水箱的四边和顶板可采用模块组装的方式进行组装。主要介绍了下水箱的厚度、底板、槽钢结构及材料选择。这些因素对整个水箱的变形有很大的影响。因此,从水箱的设计和安装角度出发,首先要满足不锈钢消防水箱的要求,以保证地基的稳定性和整体强度。

不锈钢消防水箱壁厚参数设计又称不锈钢水箱壁厚参数。不锈钢水箱的厚度参数主要由不锈钢消防水箱的尺寸决定。我们常见的不锈钢消防水箱一般位于屋顶,又称屋顶消防水箱。这种不锈钢消防水箱的尺寸一般在20吨左右,与消防稳压设备有关。通过高水箱压降和小型消防稳压装置,保证消防应急用水。

另一种不锈钢消防水箱非常少见,因为它通常放在地下室的泵房里,它还与不锈钢生活水箱共用一个不锈钢水箱。无论是简易消防不锈钢水箱还是消防生活一体化不锈钢水箱,水箱的尺寸都是根据适用范围设计的。这种水箱一般都很大,一般有几百吨。我们做过最大的不锈钢消防水箱案例:豫园国际407t异型消防水箱。这种不锈钢消防水箱不仅体积大,而且形状特殊。对于生产工艺,要求更高。甲方提出要求后,我公司技术部门将通过现场调查和测量,提出两种解决方案,以完全满足甲方的需要。

目前本工程安装已完成近三年,水箱已通过严格的时间检测,无渗漏、锈蚀、变形等迹象,得到了甲方的一致认可,2015年豫园国际将启动二期工程,并与我公司展开战略合作会更深入。届时,除不锈钢消防水箱外,我公司还将与不锈钢生活水箱及不锈钢供水成套设备合作,解决二期工程二次供水工程。

回到话题上来,我们公司产品之所以安全、稳定、可靠,取决于公司执行的不锈钢消防水箱生产标准。”向宝家水箱生产标准已通过技术监督局审核备案“从材料到设计从不打折”。

以一个18吨级不锈钢消防水箱为例,如:3M×3M×2m=18m3消防水箱,我们执行不锈钢消防水箱的厚度标准:底板采用2.0mm,不锈钢消防水箱壁厚标准,侧壁采用1.5mm厚,两侧采用1.2mm厚,顶板采用1.0mm厚。通过优化设计和专业焊接工程师安装生产,形成了不锈钢消防水箱产品,具有使用寿命长、对水质无二次污染、不变形、不褪色等特点。

如100吨不锈钢消防水箱的厚度标准:消防水箱尺寸为6m×8m×3M=144m?我公司(大江不锈钢水箱)不锈钢消防水箱壁厚执行标准为:底板采用3.0mm厚,边1:2.5mm,边2:2.0mm,边3:1.5mm,顶板1.2mm。

不同尺寸的不锈钢消防水箱,大江不锈钢水箱将根据不同的条件和压力强度进行设计,以保证我厂生产的不锈钢消防水箱的质量。

根据国家标准,水箱底板厚度为3.0cm,第一层厚度为3.0cm,第二层厚度为2.5m,第三层厚度为2.0cm,第四层厚度为1.5cm,顶板厚度为1.2cm,目前市面上的小双层板边长约为第一侧板厚度的1.5厘米,第二侧板厚度约为1.2米,双层板边长约为2.0厘米,第二侧板厚度约为1.5米。

不锈钢水箱分为:组合式不锈钢水箱、不锈钢保温水箱、圆柱形不锈钢水箱、不锈钢生活水箱、不锈钢消防水箱、球形不锈钢水箱、凸形不锈钢水箱、不锈钢水箱。不同的型号和尺寸对不锈钢水箱的厚度有不同的要求。

不锈钢水箱由标准不锈钢板组成。根据不同的三维结构设计参数,在工厂或现场采用不同厚度的模块进行焊接和装配。水箱冲压模块图分为1000×1000、1000×500和500×500标准模块。

1槽钢:

横向和纵向槽型钢座之间的距离为1m,槽型钢座的整体刚度和承载强度较差。该公司的水平和纵向通道间距为0.5m,所有接头都焊接,以确保坚实的基础和高强度。

2底板:

底板一般为折板,放在槽钢上方向相反。由于渠道间距为1m,底板受压(满水)折边处于不稳定状态,向外弯曲,造成底板不平,水箱整体变形。平底板放置在槽钢上,间距0.5,稳定不变形。

三。拉杆:

一般情况下,由于杂质含量高,不锈钢与水箱接头的焊接强度难以保证。拉杆与水箱板材质相同。焊接接头材料成分均匀耐用,溶解性好,焊接质量高,有效保证了焊接强度。

The four sides and top plate of the combined stainless steel water tank can be assembled by module assembly. This paper mainly introduces the thickness, bottom plate, channel steel structure and material selection of the lower water tank. These factors have great influence on the deformation of the whole water tank. Therefore, from the water tank design and installation point of view, first of all to meet the requirements of stainless steel fire water tank, to ensure the stability and overall strength of the foundation.

According to the national standard, the thickness of the bottom plate of the water tank is 3.0cm, the thickness of the first layer is 3.0cm, the thickness of the second layer is 2.5m, the thickness of the third layer is 2.0cm, the thickness of the fourth layer is 1.5cm, and the thickness of the top plate is 1.2cm

At present, the side thickness of the small two-layer on the market is about 1.5 cm of the thickness of the first side board, the thickness of the second side board is about 1.2 m, the side thickness of the two-layer board is about 2.0 cm, and the thickness of the second side board is about 1.5 m.

Stainless steel water tank is divided into: combined stainless steel water tank, stainless steel heat preservation water tank, cylindrical stainless steel water tank, stainless steel water tank life, stainless steel fire water tank, spherical stainless steel water tank, convex stainless steel water tank, stainless steel water tank. Different types and sizes have different requirements for the thickness of stainless steel water tank.

Stainless steel water tank is composed of standard stainless steel plate. According to different three-dimensional structure design parameters, different thickness modules are used for welding and assembly in the factory or on site.

The stamping module drawing of water tank is divided into 1000 × 1000, 1000 × 500 and 500 × 500 standard modules.

1. Channel steel:

The distance between the transverse and longitudinal groove steel seats is 1 m, and the overall stiffness and bearing strength of the groove steel seat are poor. The company's horizontal and longitudinal channel spacing is 0.5m, all joints are welded to ensure a solid foundation and high strength.

2. Bottom plate:

The bottom plate is generally a folded plate, which is placed on the channel steel in the opposite direction. Because the channel spacing is 1 m, the folded edge of the bottom plate under pressure (full of water) is in an unstable state, thus bending outward, resulting in uneven bottom plate and overall deformation of the water tank. The flat bottom plate is placed on the channel steel with 0.5 spacing, which is stable without deformation.

3. Pull rod:

In general, it is difficult to ensure the welding strength of the stainless steel joint with the water tank due to the high content of impurities. The pull rod is made of the same material as the water tank plate. The material composition of the welded joint is uniform and durable, with good solubility and high welding quality, thus effectively ensuring the welding strength.

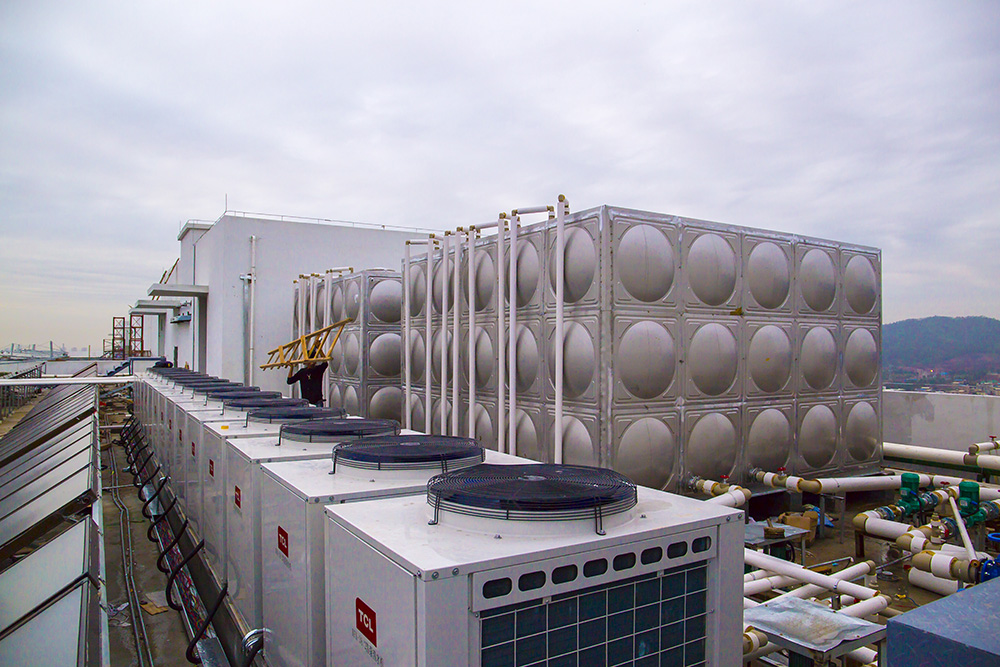

组合式不锈钢水箱案例--惠州TCL工业园,产品型号:方形水箱,产品材质:304不锈钢,施工地区:惠州...

MORE+

组合式不锈钢水箱应用案例:顺德区美芝精密500吨水箱,产品型号:方形水箱,产品材质:304、201不...

MORE+

中信戴卡是一家以轮毂生产为主的企业,工厂用水尤其是循环水、冷却用水、热水系统中应用不锈钢水箱比较多。...

MORE+

广州大型不锈钢水箱工--恒大集团,应用于办公大楼。有效容积达千吨,水箱主体高度4米。安装完毕至今已近...

MORE+